Relocate to a new factory, expand production capacity, and meet new challenges

2024-02-22 15:30

Shunkangda Medical Technology Co., Ltd. relocated to a new factory, introduced advanced equipment, and expanded production capacity to meet new challenges.

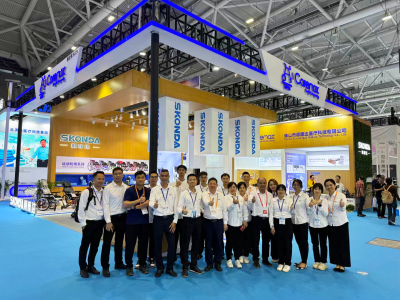

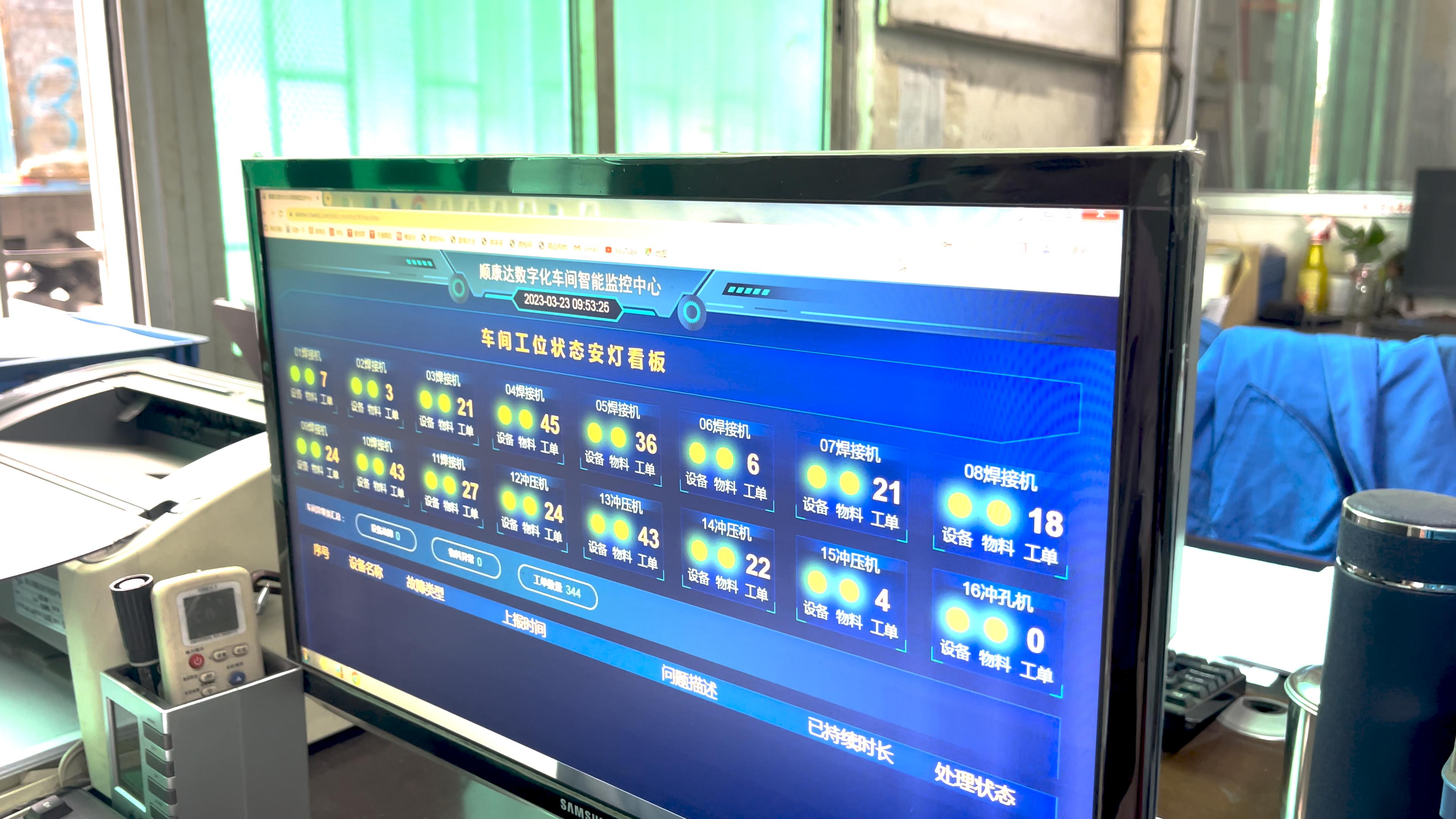

Foshan Shunkangda Medical Technology Co., Ltd. has been committed to the research and development, production and sales of medical devices, rehabilitation assistive devices and intelligent elderly care products since its establishment in August 2005. Now, in order to adapt to the growing market demand, the company decided to move to a new factory to increase production capacity and introduce more advanced equipment.

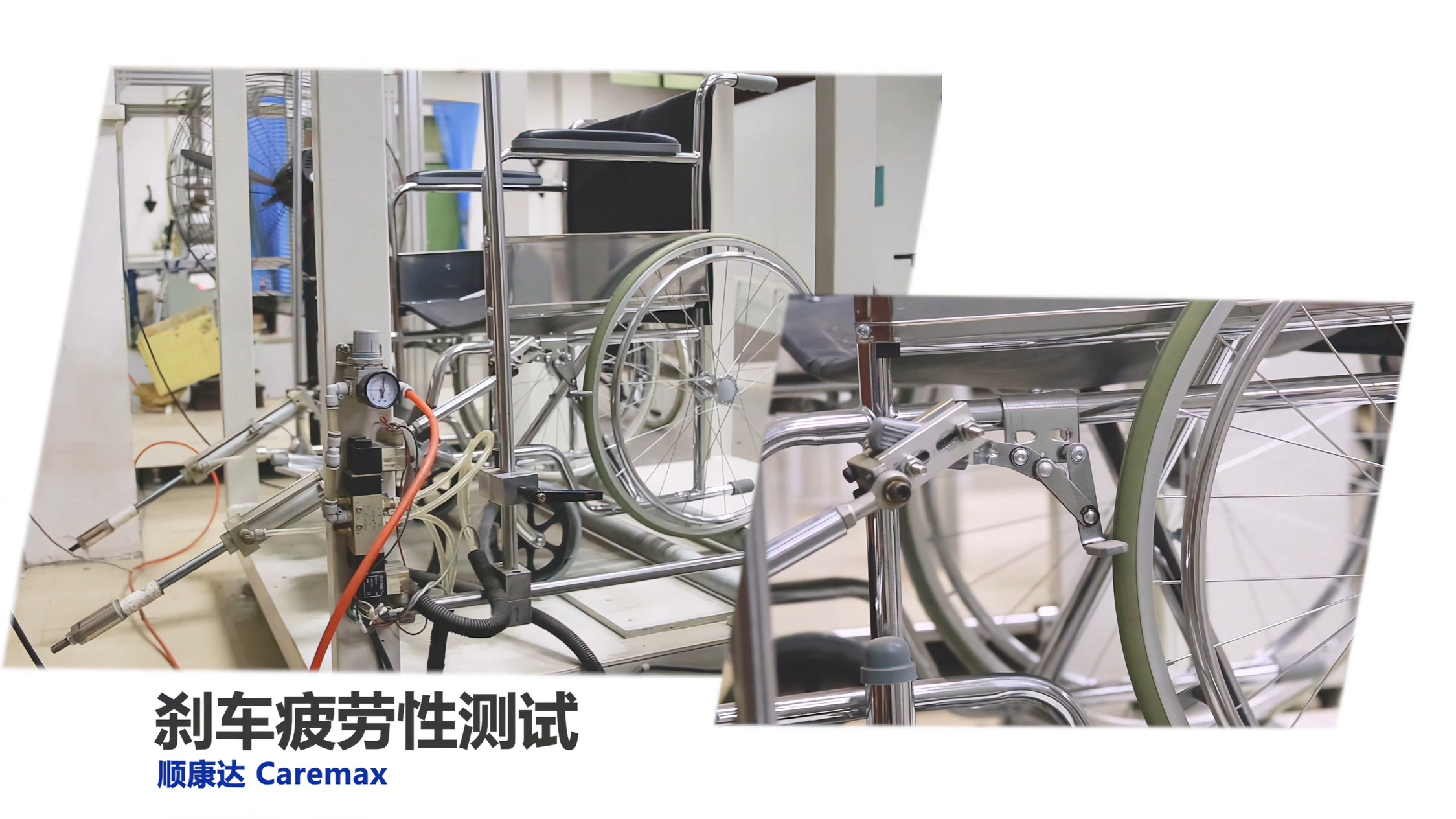

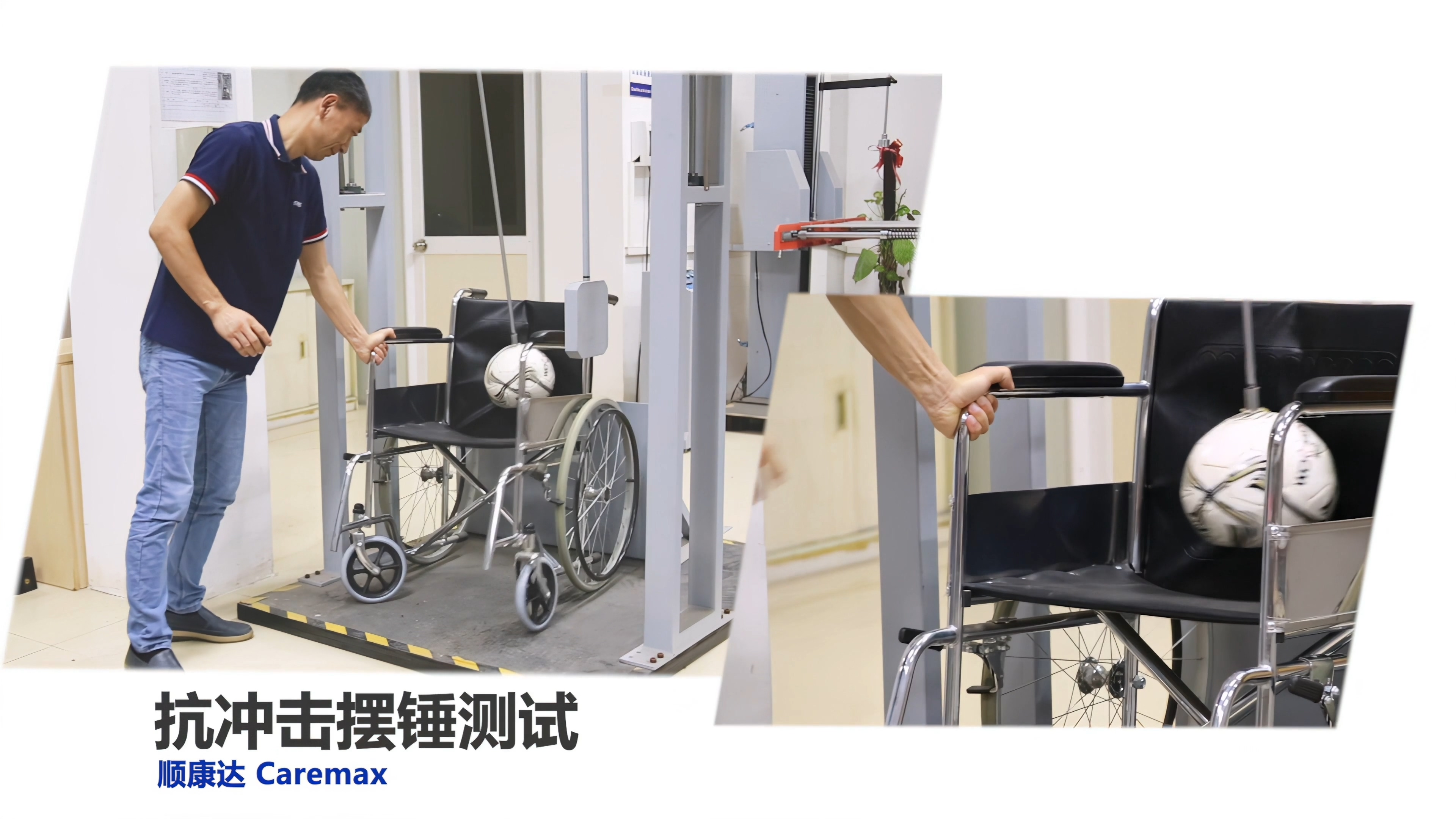

The new factory is located in Foshan City and has larger production space and modern equipment, which will greatly promote the company's production efficiency and product quality. Before the new plant was put into use, the company conducted various tests on the equipment, including brake fatigue testing, impact resistance pendulum testing, packaging anti-fall testing, etc., to ensure the stability and reliability of the equipment.

The brake fatigue test is to verify the stability and reliability of the new equipment after long-term operation. The company has specially set up a test bench to simulate braking conditions under different road conditions. After a long period of testing, it ensures that the equipment can brake reliably in emergency situations and ensure the safety of users.

The impact pendulum test is to test the resistance performance of the equipment when it is subjected to external impact. During the test, the staff used a standardized pendulum to impact the equipment and observe the deformation of the equipment and whether the internal structure was damaged to ensure that the equipment can effectively protect users in unexpected situations.

In addition, the company also conducted packaging anti-drop testing to verify the durability of the product during transportation. By simulating the various degrees of beating and squeezing of packages during transportation, companies can evaluate the rationality of packaging design to ensure that products are not damaged during transportation and are still intact when they arrive in the hands of users.

Mr. Li, general manager of Shunkangda Medical Technology Co., Ltd., said: "The putting into use of the new factory marks a new milestone for us. We have introduced a batch of advanced equipment and conducted various tests, which will further improve Our production capacity and product quality. This will help us better meet customer needs and expand market share, while also laying a solid foundation for the company's future development."

Shunkangda Medical Technology Co., Ltd. is a private high-tech enterprise with more than 300 employees. Its products cover many fields such as home medical rehabilitation and nursing equipment, sanitary supplies, mobile equipment, and medical electronic products. Currently, the company has an annual production capacity of 300,000 wheelchairs, 5 million sets of four-wheel drive assistive devices, crutches and walkers, and 3 million sets of bathroom chair armrests. Its products are exported to more than 50 countries and regions around the world.

The commissioning of the new factory will not only further enhance the company's competitiveness, but also inject new vitality and power into the continued development of Shunkangda Medical Technology Co., Ltd. in the field of medical devices.